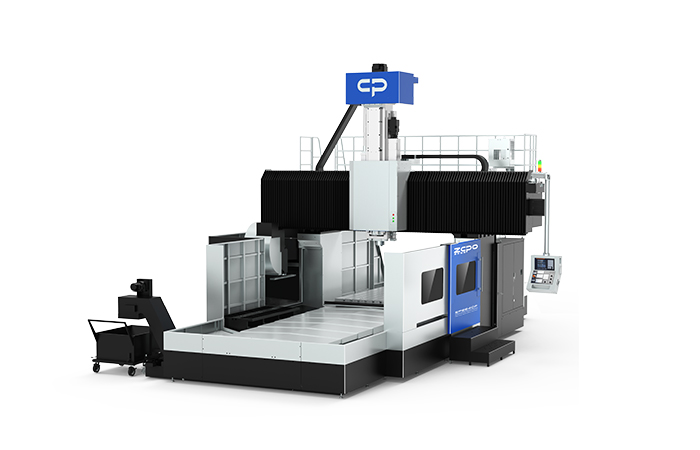

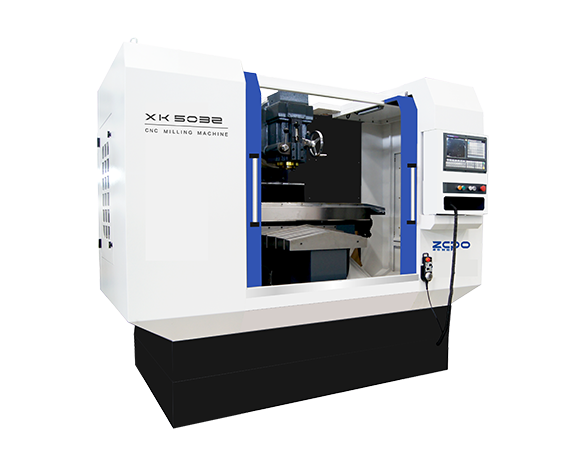

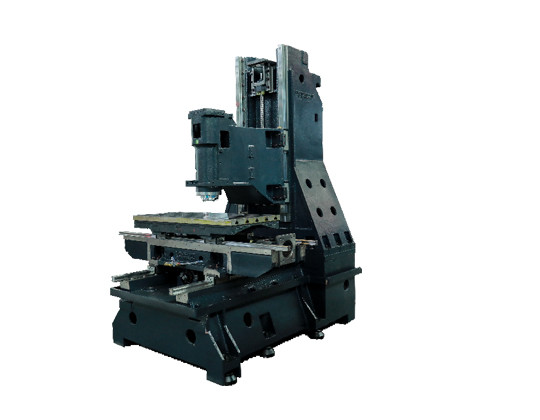

Vertical Machining Center|SEB855 Belt spindle| Rigid Structure | Ideal for Aluminum & Mold Processing | OEM/ODM Support

Vertical Machining Center

SEB855

Efficiency model

The best choice for pan-aluminum processing, high-precision molds, and parts processing

850/550/600mm

X/Y/Z axis travel

500×1000mm

Worktable size

8000rpm

Spindle speed

48/48/36m/min

Rapid feed speed

- Model

- Appearance

- Charasteristics

- Parameters

- Contact Us

High rigidity and high precision structural design

- After FEA, the integral bed with reinforcement is made of dense baked cast iron casting, which has better rigidity in the same size machine tool.

- The bed and saddle are designed with triangular stabilizing structure, which strengthens the rigidity of the main load-bearing parts, thus ensuring the stability of accuracy.

- Spindle box structure, while doing lightweight design, combined with FEA, to enhance the rigidity of the spindle box and dynamic response capability.

- The lightweight design of the moving parts further improves the dynamic response speed of the machine tool.

Easier to use and more powerful control system

Relying on the in-depth collaboration between ZOPO engineers and CNC system companies, we continuously carry out secondary development based on standard CNC systems to create multifunctional and intelligent human-machine interfaces, creating a more efficient and convenient user experience for customers.

- Selection of energy-efficient processing modes

- Tool management function

- Troubleshooting guide function

- Super powerful human-computer interaction interface.

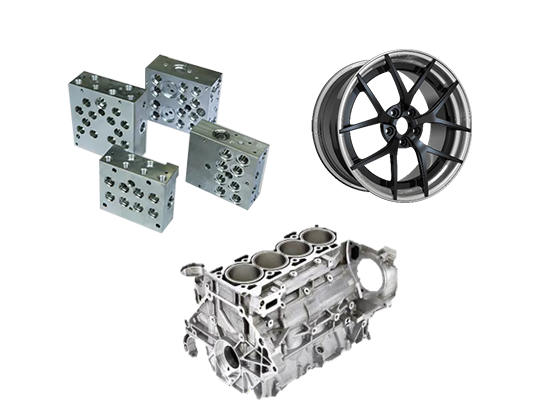

Stronger processing applications

SE series vertical machining centers have leading capabilities in the machining of non-ferrous metals. With high speed, high precision and flexible expansion space, it is the first choice for automated group line machining and is widely used in high-tech industries such as automotive parts, molds and aerospace.

- Larger machining range

- Higher machining stability

- Faster dynamic response

- Higher metal removal capability

Working range

- X/Y/Z axis travel

- 850/550/600mm

- Distance from column to spindle center

- 597mm

- Distance from table surface to spindle nose

- 120-720mm

Worktable

- Worktable size

- 500x1000mm

- T-slot size

- 5-18*100mm

- Max. load bearing of worktable

- 600kg

Spindle

- Spindle hole taper

- BT40

- Main motor power

- 11/15KW

- Spindle speed

- 8000(belt)rpm

Feed

- Max. feed speed

- 12000mm/min

- Rapid feed speed

- 48/48/36m/min

Tool magazine

- Tool magazine capacity

- 24T

- Tool change time

- 2.5S

Machine

- Machine dimension

- 2650*2700*2850mm

- Machine weight

- 4800kg

Contact ZOPO Intelligence

- Product Price Consultation

- Phone

Support

- Phone

- *Title

- *Content