Why Did the World's No.1 Sewing Machine Manufacturer Trust ZOPO’s Horizontal Machining Centers?

Why Global Leaders Trust ZOPO to Stay Ahead

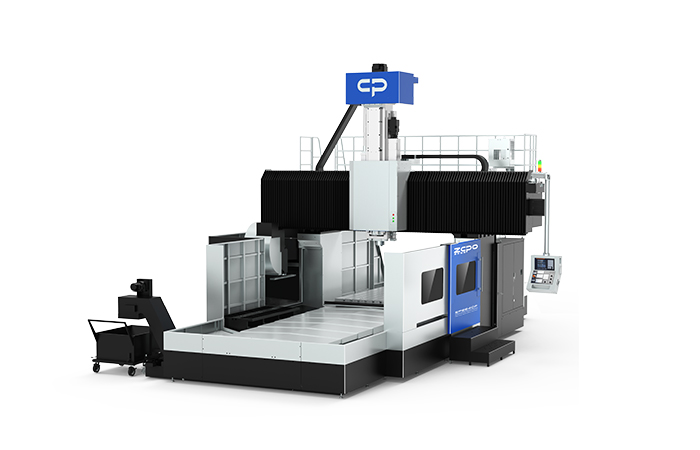

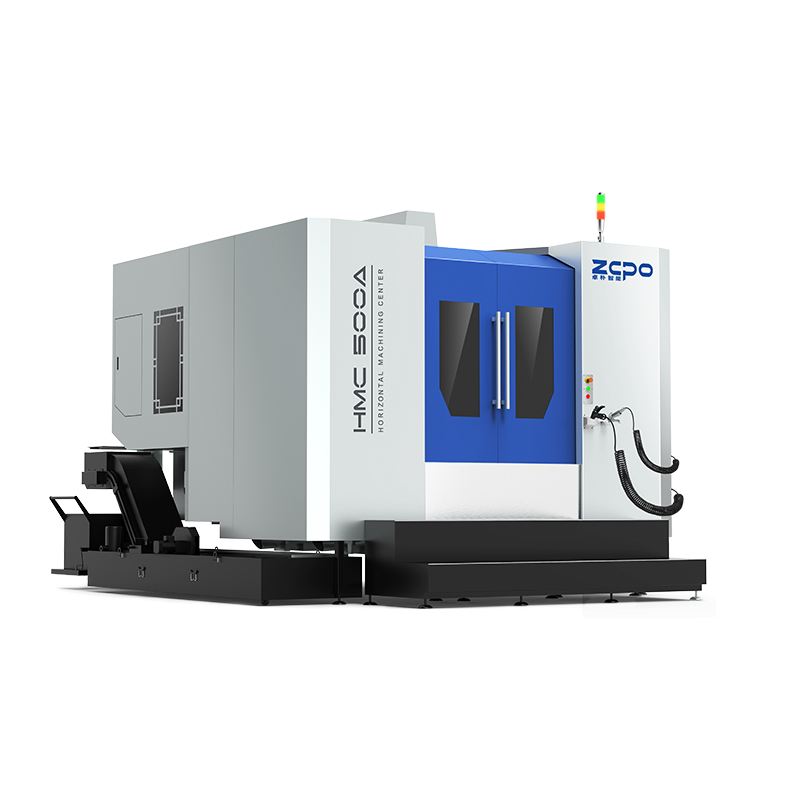

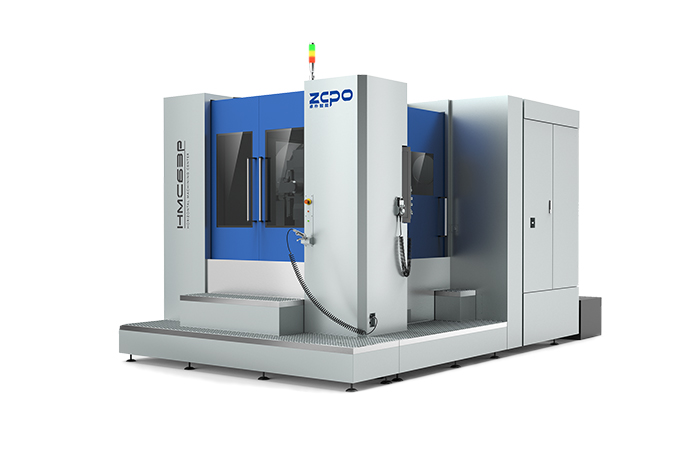

In the high-stakes arena of precision manufacturing, even industry giants face a critical question: How do we stay ahead? For the world's leading sewing machine manufacturer, the answer was clear—ZOPO's Horizontal machining centers. Jack Sewing Machine Co., Ltd. made a decision to invest in 30 sets of ZOPO HMC63 speaks volumes. Here's why global leaders rely on ZOPO to power their production lines.

Innovation Meets Legacy: The ZOPO Advantage

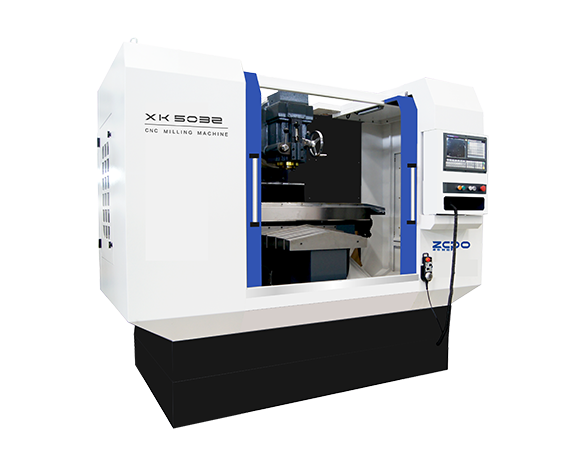

With over 20 years of R&D expertise and 10+ core patents, ZOPO redefines precision machining. Its horizontal machining centers are engineered not just to meet industry standards—they set them. From automotive giants to 5G tech pioneers, ZOPO's horizontal machining centers deliver unmatched performance, flexibility, and reliability.

What Makes ZOPO's Horizontal Machining Centers the Smart Choice?

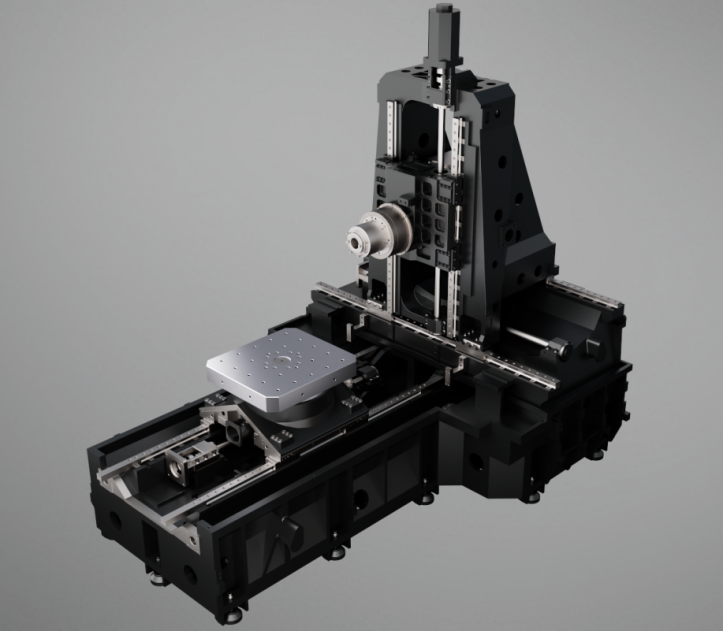

1.Revolutionary Design for Unshakable Stability

ZOPO's positive T and inverted T composite structures are game-changers. The X-axis's high-low-level design elevates guide rails, boosting bed rigidity by 30% compared to traditional models. Combined with an M-type rib plate bed and gantry-frame column, these horizontal machining centers resist deformation, ensuring micron-level accuracy even under heavy loads.

2.Smarter Workflows, Faster Output

Switch seamlessly between single or double worktables with intelligent automation. The positive T design keeps the spindle stationary during boring, minimizing vibration for ultra-precise finishes. Need speed? The inverted T model's rapid column movement slashes drilling and tapping cycles by 10-25%, while dual-side chip removal keeps production lines running smoothly.

3.Built to Outperform, Engineered to Last

ZOPO's thermal deformation control contributes a lot. Optimized heat dissipation and spacious cutting zones prevent overheating, extending tool life much longer. Whether machining engine blocks or medical implants, ZOPO's horizontal machining centers deliver consistent quality—batch after batch.

Industries We Power

ZOPO's horizontal machining centers aren't just machines—they're solutions. Tailored for:

Automotive: Engine blocks, gearbox housings, and EV components.

Aerospace: High-tolerance molds and structural parts.

Medical: Surgical instruments and implant-grade precision.

5G & Beyond: Ultra-fine communication device parts.

Customizable to your needs: ZOPO horizontal machining centers adapt as your business grows.

Why Settle for Less?

When the world's most demanding manufacturers choose ZOPO, it's not just about technology—it's about trust. ZOPO horizontal machining centers aren't just tools; they're your competitive edge. A machine with both charm and power.

Ready to transform your production line? Contact ZOPO today and engineer the future, one precision cut at a time.