Lathes and Turn-Mills: How to Expand Your Capabilities for Machining Rotating Parts?

Standard Lathes: The Core of Rotating Part Machining

A lathe is designed to machine parts by rotating the workpiece while the cutting tool removes material. This machining principle makes lathes ideal for producing components with rotational symmetry.

Typical Applications of Standard Lathes

1. Shafts and axles

2. Bushings and sleeves

3. Rings and flanges

4. Threaded components

Modern CNC lathes have significantly improved upon traditional manual machines by offering:

1. Higher positioning accuracy

2. Stable spindle performance

3. Consistent surface finish

4. Automated and repeatable production

For many manufacturers, standard CNC lathes remain the most cost-effective and reliable solution for high-precision turning tasks.

At ZOPO , our CNC lathe series is engineered with rigid machine structures, high-quality spindles, and precise feed systems — ensuring excellent accuracy and long-term stability in daily production.

Limitations of Conventional Turning in Modern Manufacturing

While standard lathes excel at turning operations, modern parts increasingly require additional machining features, such as:

1. Flats and keyways

2. Cross holes and angled holes

3. Slots and contours

4. Multi-surface machining

Using separate machines for turning and milling means:

1. Multiple setups

2. Longer production cycles

3. Higher risk of alignment errors

4. Increased labor and handling costs

This is where turn-mill technology becomes a strategic upgrade rather than a luxury.

Turn-Mill Lathes: Combining Turning and Milling in One Machine

A turn-mill lathe (also known as a turning and milling center) integrates turning and milling operations into a single machine platform. It allows manufacturers to complete complex rotating parts in one setup, dramatically improving efficiency and accuracy.

Key Advantages of Turn-Mill Machining

1. Reduced setup time

2. Higher dimensional consistency

3. Improved machining accuracy

4. Shorter overall lead times

5. Lower work-in-process inventory

By performing turning, milling, drilling, and tapping in one machine, turn-mill lathes unlock new possibilities for high-efficiency composite machining.

How ZOPO Turn-Mill Solutions Improve Precision and Efficiency

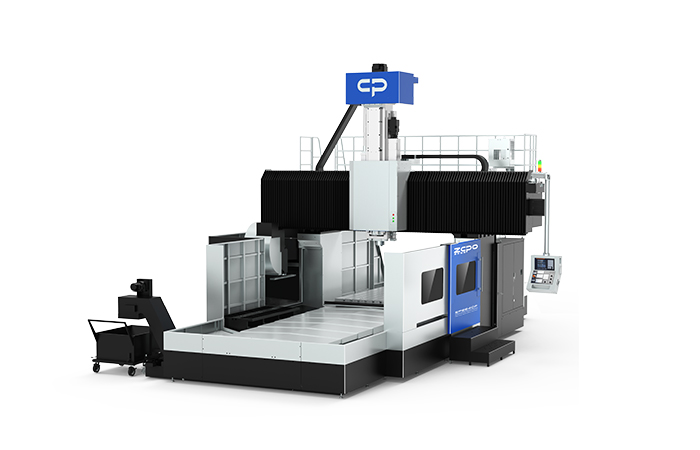

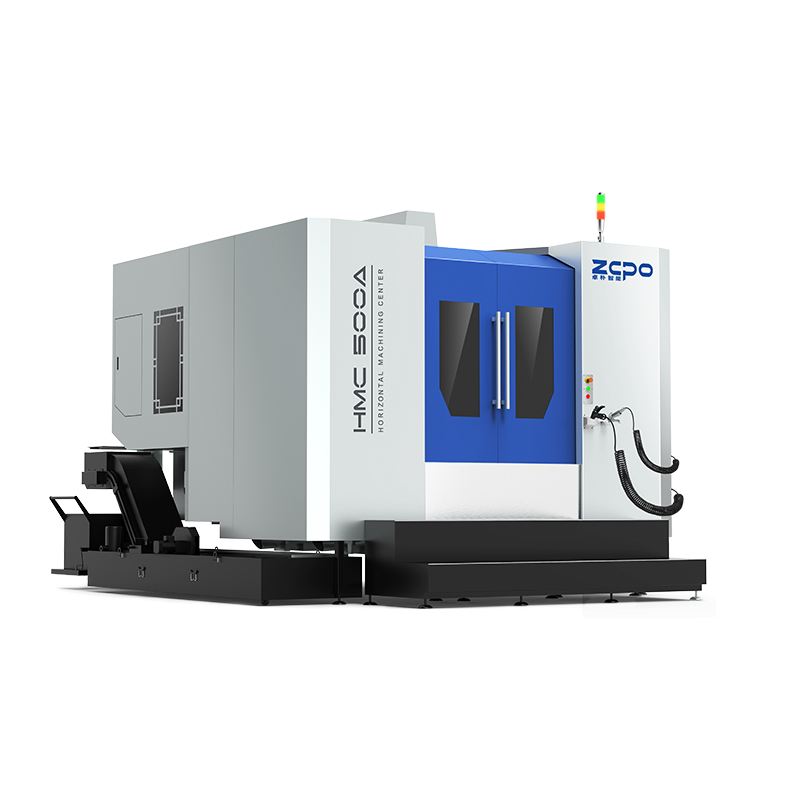

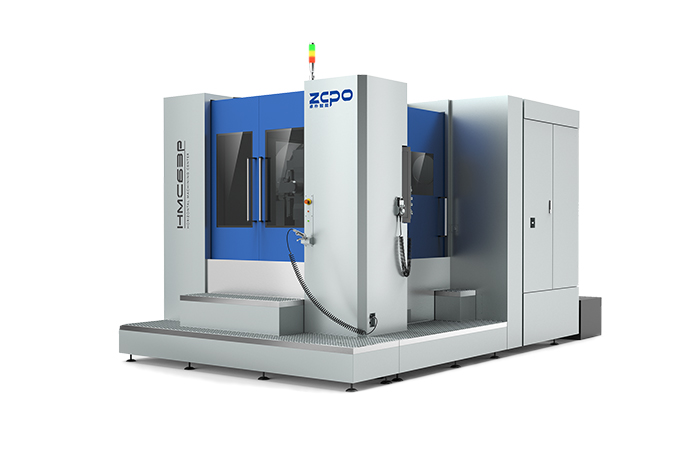

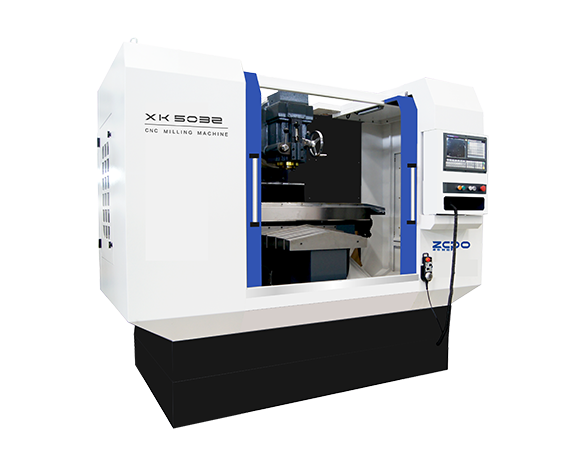

ZOPO Intelligent Equipment provides a complete range of turning and turn-mill solutions designed to meet the evolving needs of modern manufacturing.

ZOPO Turning & Milling Capabilities

1. High-rigidity machine beds for stable cutting

2. Powerful spindle systems for heavy-duty and high-speed machining

3. Multi-axis configurations for complex geometries

4. Intelligent CNC systems for efficient programming and automation

ZOPO's turn-mill machines enable manufacturers to:

1. Reduce machining steps

2. Improve geometric accuracy

3. Increase machine utilization

4. Respond faster to customized and small-batch orders

Complete Rotating Part Machining Solutions from ZOPO CNC

ZOPO CNC does not simply offer machines — we provide complete rotating part machining solutions.

Whether your production focuses on:

1. High-volume turning

2. Precision shaft machining

3. Complex parts requiring turning and milling

4. Future-ready flexible manufacturing

Our lathe and turn-mill product lines allow you to scale from conventional turning to advanced composite machining, ensuring a smooth and cost-effective upgrade path.

When Should You Upgrade to a Turn-Mill Machine?

You should consider a turn-mill solution if:

1. Your parts require both turning and milling features

2. Setup time is limiting productivity

3. Tolerance consistency is difficult to maintain

4. Labor and handling costs are increasing

In such cases, investing in a ZOPO turn-mill lathe can significantly enhance your competitiveness by improving efficiency, precision, and delivery speed.

Conclusion

Standard lathes remain essential for precision turning, but as part complexity increases, turn-mill machines become the key to unlocking higher efficiency and accuracy.

With a complete range of CNC lathes and turn-mill solutions, ZOPO helps manufacturers build a flexible, high-performance machining system for rotating parts — today and in the future.