CNC Machine Selection Guide: Beyond Vertical vs. Horizontal — 3 Key Factors You Must Consider

Workpiece Size & Machine Travel — The First and Most Important Step

Machine travel determines everything. No matter how powerful the spindle is, a CNC machine is useless if your part simply doesn't fit.

How to confirm the right machine travel:

1. Check max part length, width, height

2. Add tool length and vise/fixture space

3. Leave 20–30% safety allowance for future flexibility

4. Consider upgrade paths (4th axis or rotary table)

Typical Examples:

1. Mold bases → require longer Y/Z travel

2. Aluminum parts → large in size but light cutting

3. Automotive steel components → compact but need strong rigidity

ZOPO CNC Advantage:

ZOPO CNC offers full-size travel options from:

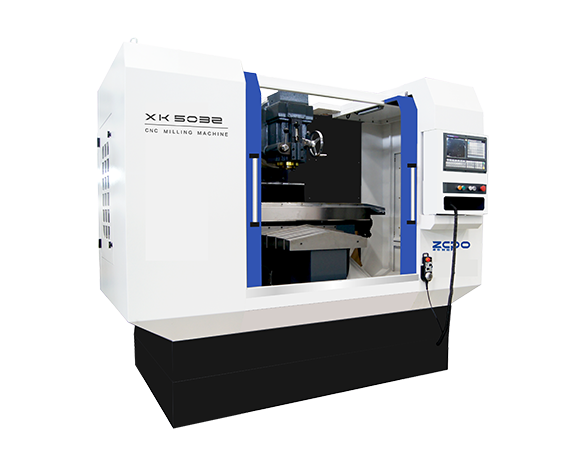

1. Small VMC for precision components

2. Standard VMC for general machining

3. Large VMC for mold manufacturing

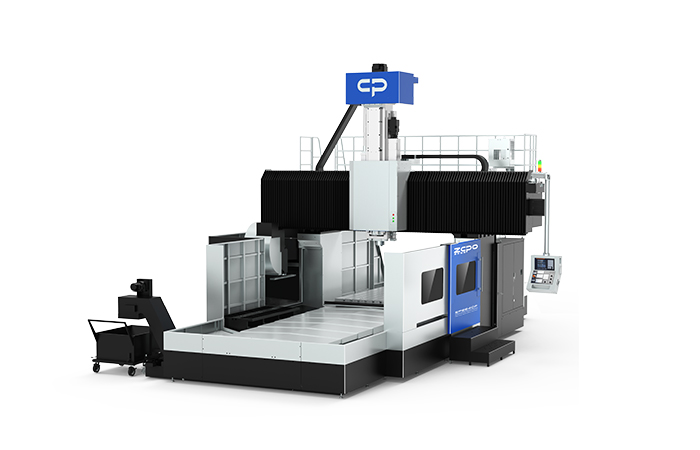

4. Double Column Centers for oversized parts

Material Type & Cutting Capability — Choose the Right Spindle & Structure

Different materials place very different demands on the machine.

If machining aluminum:

1. High-speed spindle (12,000–20,000 rpm)

2. Fast acceleration

3. High feed rate

4. Strong cooling

If machining stainless steel or tool steel:

1. High torque spindle (Gear-head or direct-drive)

2. Heavy-duty structure

3. Excellent vibration control

4. Large-diameter ball screws

Why it matters:

The right spindle prevents tool breakage, reduces cycle time, and improves surface finish.

ZOPO CNC Cutting Capability Strengths:

1. High-torque gear-head spindles for steel and heavy cutting

2. High-speed direct-drive spindles for aluminum

3. Thickened machine casting for stability

4. Wide-base column design to reduce vibration

Batch Size & Automation Requirements — Think Beyond the Machine

Your production volume determines whether you should invest in automation.

For small batch / multi-variety production:

1. Choose VMC

2. Low setup cost

3. Fast job change

4. Easier operation

5. Suitable for prototypes and repair work

For medium to large batch production:

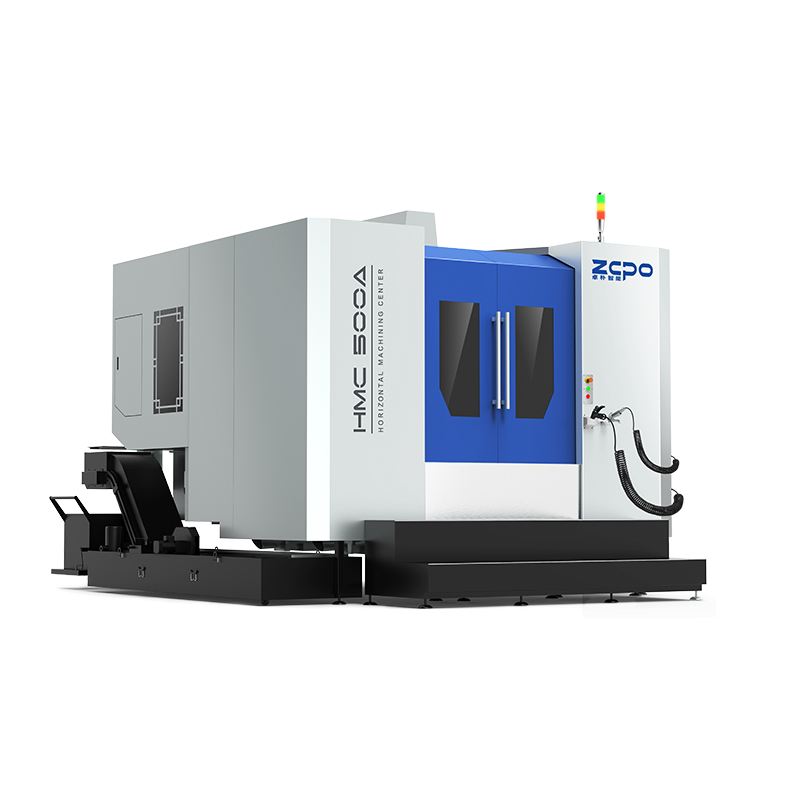

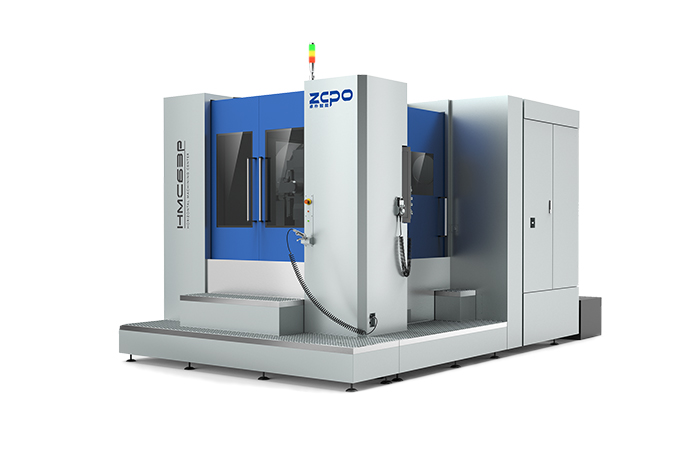

1. Choose HMC or automation-equipped VMC

2. Dual-pallet automatic change

3. Better chip removal

4. Continuous machining

6. If planning for future automation:

ZOPO CNC supports:

1. Pallet changers

2. Rotary tables

3. Probing systems

4. Robotic loading/unloading

5. Tool magazine upgrades

Why Choose ZOPO CNC? — Practical Experience + Strong Manufacturing Capabilities

ZOPO is a professional machining center manufacturer with:

1. 20+ years of design & manufacturing experience

2. Complete product range: VMC / HMC / Double column machining center / 5-axis

3. Full international support for installation, service & training

4. High-rigidity structure and stable accuracy for long-term reliability

5. CE-certified machines with overseas market experience

Our machines serve industries including mold making, automotive, aerospace, machinery parts, and metal fabrication across 50+ countries.

Conclusion

Selecting the right CNC machine is not difficult—if you know where to look. Instead of focusing only on vertical vs. horizontal, always evaluate:

Workpiece size & travel – Does the machine fit your part?

Material & cutting capability – Can the spindle handle your cutting load?

Batch size & automation – Which layout gives you the best productivity?

If you make the right decision today, you save years of cost tomorrow.