CNC Horizontal Machining Center | ZOPO Horizontal Machine Center Solutions

Introduction: Why Horizontal Machining Centers Matter

In the world of precision manufacturing, CNC horizontal machining centers play a critical role in boosting productivity, accuracy, and automation readiness. Unlike vertical machining centers, horizontal machine centers allow chips to fall away from the work area, offer multi-face machining in a single setup, and integrate seamlessly with pallet changers for unattended production.

Global leaders such as Haas and Makino have long highlighted the efficiency and versatility of horizontal machining. At ZOPO , we take these advantages further by offering a comprehensive lineup of horizontal machine centers designed for automotive, aerospace, mold making, energy, and general engineering industries.

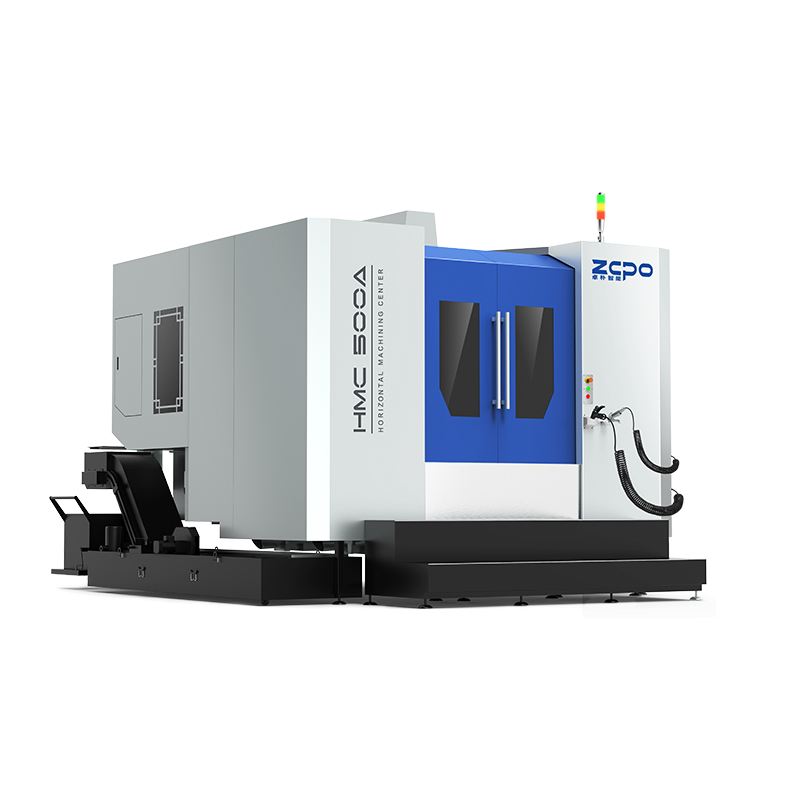

What Is a CNC Horizontal Machining Center?

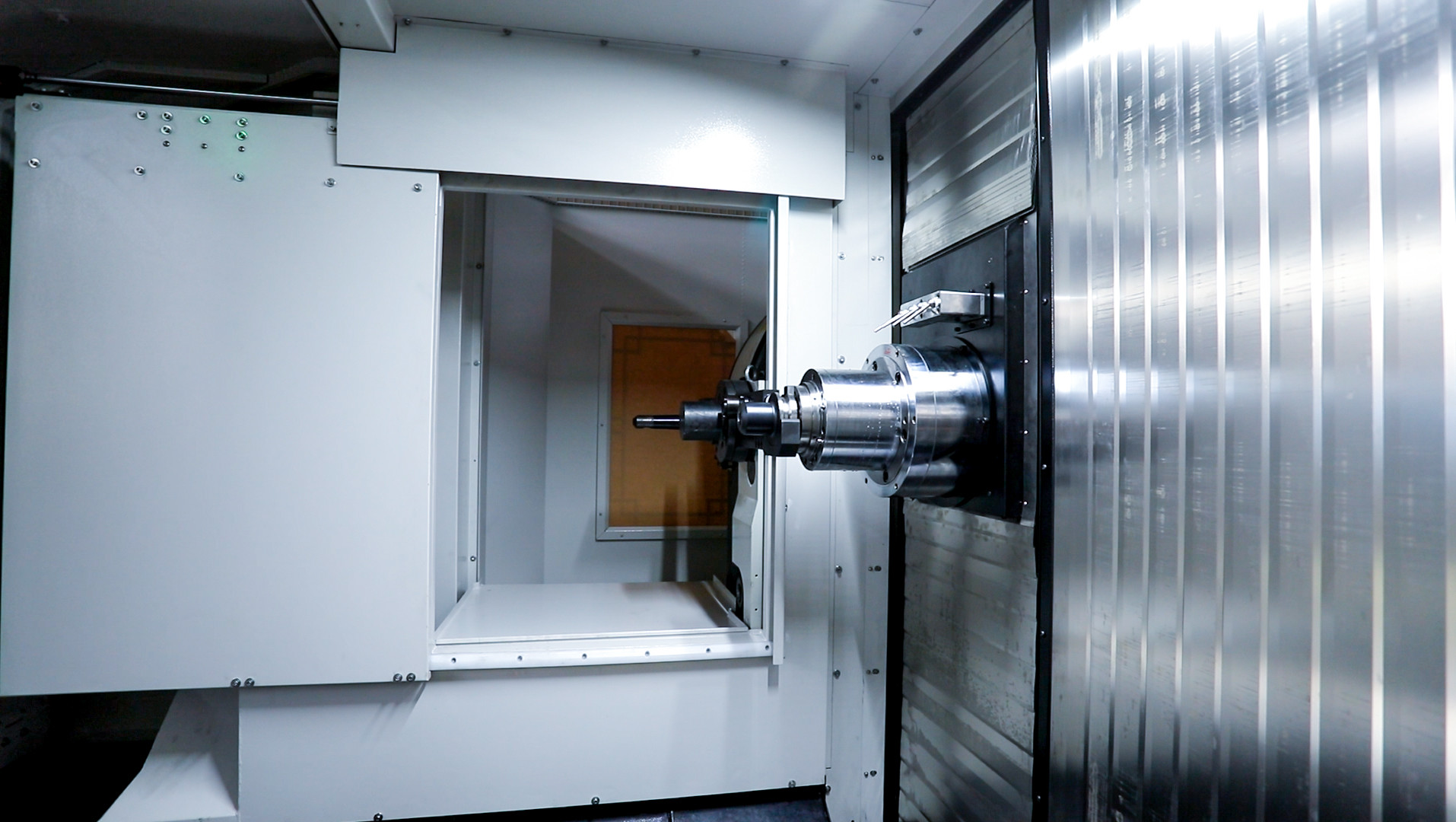

A CNC horizontal machining center is a high-precision machine tool where the spindle is positioned horizontally. This design provides:

Superior Chip Evacuation – gravity assists chip removal, ensuring cleaner cutting zones.

Multi-Sided Machining – tombstones and rotary tables allow multiple surfaces to be machined in one setup.

High Tool Capacity – large magazines reduce changeovers and extend unattended operation.

Automation Ready – pallet systems enable lights-out manufacturing and higher spindle utilization.

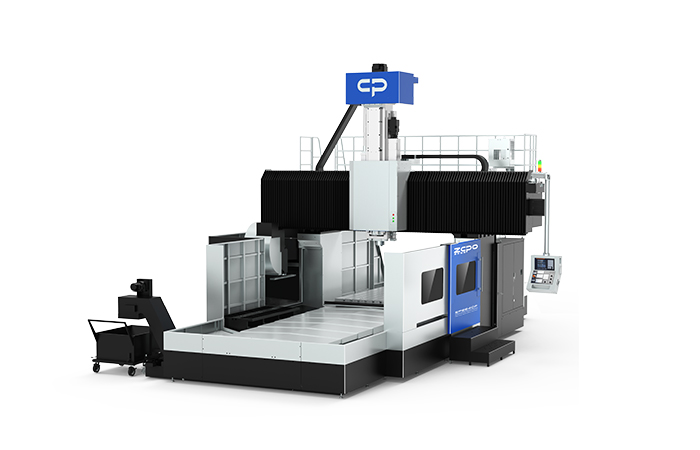

ZOPO CNC: A Legacy of Precision and Innovation

Founded on the heritage of Shanghai NO.7 Machine Tool Factory (1928), ZOPO brings nearly a century of machining expertise into every horizontal machining center we build.

Why choose ZOPO?

Over 200 product models including inverted T-type and positive T-type horizontal machining centers.

Industry versatility: trusted by automotive, aerospace, energy, 3C electronics, and heavy machinery sectors.

Quality assurance: every machine undergoes precision testing with ZEISS CMM, ball bar calibration, and thermal analysis.

Customization & scalability: tailored solutions for your unique production line.

How ZOPO Compares to Industry Benchmarks

Haas Horizontal Mills – known for modular, cost-effective solutions, great for shops upgrading from verticals.

Makino Horizontal 4-Axis/5-Axis – leading in high-speed, high-performance machining, often chosen for aerospace.

ZOPO Horizontal Machining Centers – combine robust build, high customization, and localized service, making them an ideal choice for manufacturers who need global-level precision with tailored flexibility.

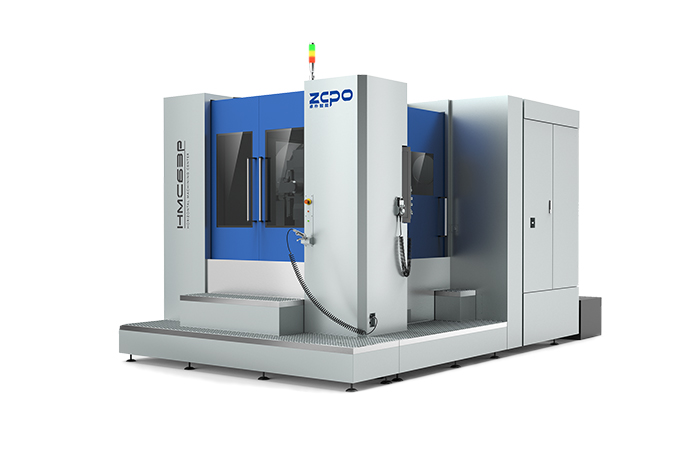

Key Features of ZOPO CNC Horizontal Machining Centers

| Feature | ZOPO Advantage | Customer Benefit |

| T-Type Structures | Inverted & Positive T-frame designs | Maximum rigidity & stability |

| High-Precisin Spindles | Dynamic balancing &calibration | Superior accuracy & surface finish |

Large Tool Magazines | High-capacity ATC options | Reduced downtime & tool changes |

Automation-Ready Pallets | Integrated APC systems | Lights-out manufacturing |

Proven QCSystems | ZEISS CMM & thermal imaging | Reliable, repeatable results |

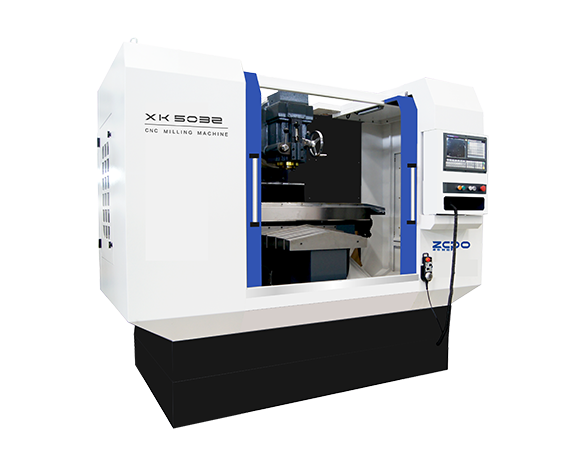

Industries That Trust Horizontal Machining Centers

Automotive – engine blocks, gear housings, transmission cases

Aerospace – structural aluminum parts, high-strength alloys

Mold & Die – complex, multi-surface cavity machining

General Engineering – prismatic parts requiring accuracy and throughput

ZOPO's horizontal machining centers are designed to tackle these industries'toughest challenges with precision, stability, and efficiency.

Smart Manufacturing with CNC Horizontal Machining Centers

A CNC horizontal machining center performing in a smart, connected manufacturing environment. The image should showcase IoT devices, predictive maintenance software, and automated monitoring systems running on large display screens in a high-tech workshop.

Conclusion

A final shot of a ZOPO CNC horizontal machining center working in a high-tech production environment, with a focus on a workpiece in progress. The machine should look robust, precise, and futuristic, embodying ZOPO's legacy of excellence