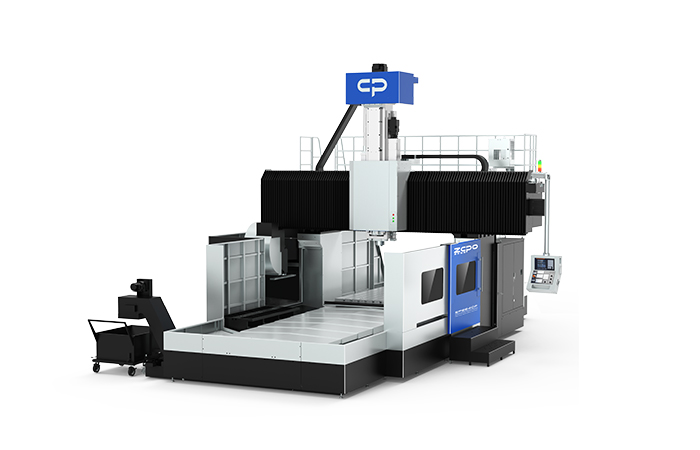

CNC Double Column Machining Center | High-Performance Dual Column Milling by ZOPO

Introduction: Precision Meets Power

For manufacturers handling large molds, heavy dies, or complex structural parts, a CNC Double Column Machining Center—also known as a Gantry Milling Machine—is the ultimate solution for high-precision, heavy-duty machining.

At ZOPO,our Double Column Machining Centers combine decades of engineering expertise with cutting-edge CNC technology, delivering exceptional rigidity, accuracy, and reliability for industries worldwide, including automotive, aerospace, energy, and heavy machinery.

What Is a CNC Double Column Machining Center?

A Double Column Machining Center features two parallel vertical columns supporting a rigid crossbeam, on which the spindle head moves. This design provides:

High rigidity and reduced vibration under heavy cutting

Large work envelope to accommodate oversized parts

Precise multi-axis motion for complex machining tasks

While often called a Gantry Machining Center in some regions, the structure and purpose are identical: providing maximum stability and precision for heavy workpieces.

Key Components:

Dual vertical columns and crossbeam (gantry)

Heavy-duty worktable and linear guideways

High-speed spindle with automatic tool changer (ATC)

CNC controller (FANUC, Mitsubishi, Siemens)

Coolant-through spindle and chip removal system

Advantages of ZOPO Double Column Machining Centers

Superior Rigidity and Stability:

The dual-column frame minimizes deflection and vibration, ensuring consistent accuracy even with heavy cuts.

Large Work Envelope:

Wide crossbeam and long table travels allow machining of oversized molds, die sets, and structural components.

Precision and Reliability:

Structural symmetry and thermal compensation deliver repeatable precision for high-value parts.

Flexibility Across Industries:

Ideal for mold & die, aerospace, energy, automotive, and heavy machinery, capable of cutting steel, aluminum, and titanium.

Efficient Production:

Advanced CNC control enables multi-axis simultaneous machining, reducing cycle time and improving throughput.

ZOPO CNC Advantage: Experience, Expertise, Authority

At ZOPO , we are experts in heavy-duty CNC machining. Our Double Column Machining Centers are designed for:

High-strength Meehanite cast iron structure for stability and vibration damping

Heavy-duty linear guides and precision ball screws for smooth, accurate motion

High-speed spindle options for roughing and finishing

Smart CNC controllers with user-friendly interface

Customizable configurations to match your specific application

With over 20 years of industry experience, ZOPO has supplied thousands of double column machining centers globally, ensuring consistent quality, reliability, and after-sales support.

Applications Across Industries

ZOPO CNC Double Column Machining Centers excel in:

Automotive: engine blocks, molds, dies

Mold & Die Manufacturing: injection molds, stamping dies

Aerospace & Defense: aluminum and titanium structural parts

Energy & Power: turbine components, valve bodies

Heavy Equipment: machinery frames, large steel castings

Each machine undergoes stringent testing for thermal stability, repeatability, and precision, ensuring long-term performance.

Why Manufacturers Choose ZOPO CNC

Decades of experience in CNC machine design and production

Global client base across Asia, Europe, and North America Custom solutions for specific machining requirements

Reliable after-sales support and fast spare parts delivery

Proven expertise in precision, stability, and productivity

At ZOPO,we don't just sell machines—we provide complete machining solutions tailored to your industry needs.

Conclusion: Maximize Your Production with ZOPO CNC

A CNC Double Column Machining Center is the heart of modern heavy-duty machining, delivering precision, stability, and efficiency for large and complex workpieces.

With ZOPO,you gain a trusted partner in innovation, engineering, and global service—helping you produce high-precision parts efficiently and reliably.